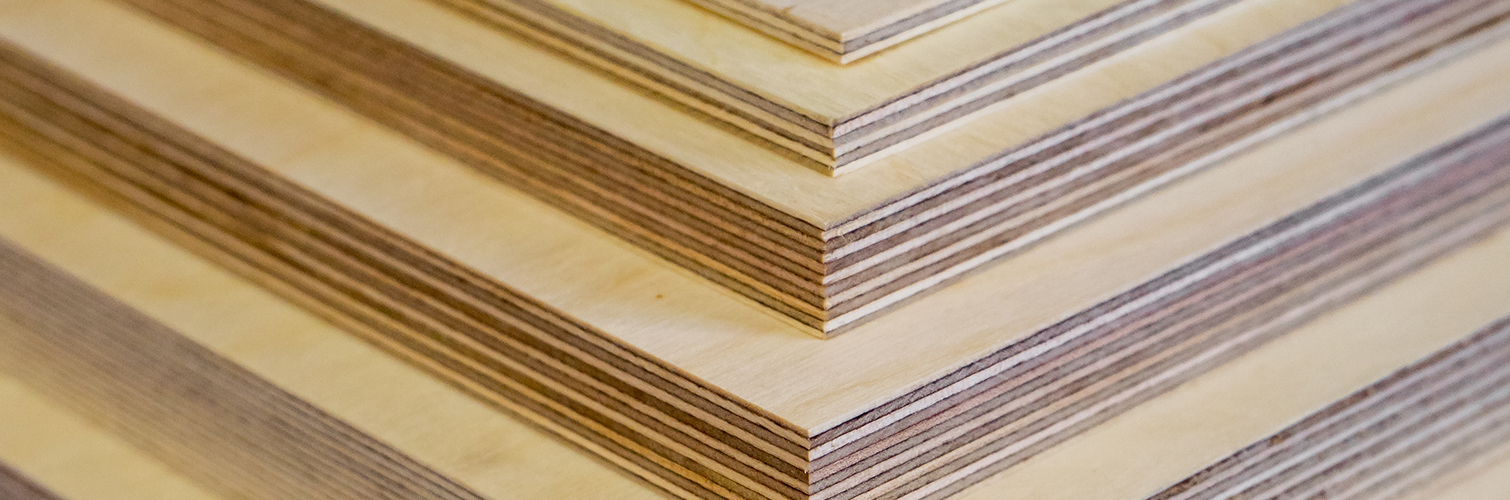

Plywood

Plywood by Virgolam is made of premium quality natural wood with the best wood refining and bonding process. The result is an exclusive range of plywood categories, which are used in various different applications. Virgolam, one of the leading Plywood Manufacturers in India brings to its customers an elite product range including General plywood, Block Board, Shuttering plywood, Marine plywood, Flexi plywood and Chequered plywood. Made up of thin layers of wood bonded together with a strong adhesive, each type of plywood has distinct application offering strength and style to any surface.

General Purpose Plywood

Veneers from high quality logs are mechanically dried and they undergo stress relieving process, which are assembled in such a way to form a balanced construction. High quality fortified synthetic resins are used for gluing the veneers. Glue line is poisoned by special formulations of chemicals to make Virgo Plywood safe against borers. It is hot pressed under proper temperature and more than 16 Kg/cm2 specific pressure. Conditioning is done after pressing, followed by preservative treatment.

Applications

Cabinets, Almirahs and other furniture, Door Partitions, Shelves and other interior applications; Roofing, Fencing, and other external applications.

Technical Specification

| Test | Required Value | Observed Value |

|---|---|---|

| Moisture Contents | 5%-15% | As per ISI Req. |

| Dimension | Length + 5mm, Width +2mm Thickness 2-8mm + 5% <6mm +10% |

With limit |

| Sp. Gravity | As per ISI Req. | |

| Resistance to Water | ||

|

(3 cycles of 8 hr boiling and 16 HR.Drying at 65oC) |

||

| -Adhesion to plies | Min.Pass Standard | Excellent |

| Resistance to Micro- Organism | ||

| - Adhesion to plies | Min.Pass Standard | Excellent |

| Stactic Bending Test | ||

| a) Modulus of Elasticity | ||

|

- along the grain

Avg.

|

Min. 5000N/sq.mm | As per ISI Req. |

|

- across the grain

Avg.

|

Min. 2500N/sq.mm | As per ISI Req. |

| b) Modulus of Rupture | ||

|

- along the grain

Avg.

|

Min.40N/sq.mm | As per ISI Req. |

|

- across the grain

Avg.

|

Min. 20N/sq.mm | As per ISI Req. |

Block Board

These are made out of excellent quality of Plantation Timbers. Logs are quarter sawn into Planks using SDR method, which are chemically treated and well seasoned before converting into battens in a multiple ripsaw. Battens are sandwiched between two glued mechanically dried veneers and are pressed in hot press under accurate temperature and pressure. Quarter sawing of logs and proper seasoning of planks make it dimensionally stable and treatment of planks, poisoning of glue line and preservative treatment of finished block board make Virgo durable and safe against borers.

Applications

Cabinets, Almirahs and other furniture, Door Partitions, Shelves and other interior applications; Roofing, Fencing, and other external applications.

Technical Specification

| Test | Required Value | Observed Value |

|---|---|---|

| Dimesnional Changes Caused by Humidity | ||

| a) Changes, mm from 65% RH to 90% RH | +1mm Max | As per ISI |

| from 65% RH to 90% RH | -1mm Max | -Requirement |

| b) Local Planeness | <1/150 | As per ISI |

| c) At the extreme range of Humidity | No de-lamination at the extreme range of Humidity |

No de-lamination Observed |

| Adhesion of the plies | Minimum pass standard | Excellent |

| Resistance of water | No de-lamination after 72 hours boiling |

No de-lamination |

| Resistance of water | No appreciable sign of seperation at edges. |

No separation at edges |

| Modulusof Elasticity | Min.5000 N/sq.mm | As per ISI Req. |

| Modulus of Repture | Min.50 N/sq.mm | As per ISI Req. |

Shuttering

Virgo offers a high quality Shuttering IS : 4990, Shuttering Plywood. It is a multi functional product, which can be used in construction industry for buildings, bridges, heavy industry and structures etc. for use on walls, slabs, columns and beams etc. In Virgo Shuttering Plywood, compression is about 60% more as compared to ordinary Film Face Shuttering plywood available in market. Extra compression leads to better nailing and screw holding properties. Its load bearing capacity is also enhanced due to extra compression. It is manufactured by selecting quality veneers impregnated with modified RPF resin for longer life and better performance in all applications. Impregnation of resin in veneers is more than 30% to the weight of veneers. Virgo offers a high quality Shuttering Plywood and Concrete Shuttering Plywood. It is a multi functional product, which can be used in buildings, bridges, heavy industry and structures construction etc. Extra impression leads to better ridges and long life holding properties. Its load bearing capacity is also enhanced due to extra compression.

Applications

Partition and paneling, ceilings in public rooms and corridors, floor underlayment, computer rooms, furniture, bus bodies, railway coaches, milk booths, sign boards, insert in panel doors, storage racks.

Technical Specification

| Test | Required Value | Observed Value |

|---|---|---|

| Moisture Contents | Moisture Contents | As per ISI Req. |

| Glue Shear Strength | Min. IND . 1100 N | As per ISI |

| ( Dry State ) | Min. AVG. 1350 N | Requirement |

| Adhesion to plies | Min.Pass Standard | Excellent |

| Glue Shear Strength | Min. IND . 800 N | As per ISI |

| ( Dry State ) | Min. AVG. 1000 N | Requirement |

| Adhesion to plies | Min.Pass Standard | Excellent |

| Mycologival Test | No.Sign of Seperation | No Separation |

| Glue Sheer Strength | Min. IND . 800 N | As per ISI |

| Min. AVG. 1000 N | Requirement | |

| Tensile Strength | 32.5 N/sq.mm | As per ISI |

| Along the Grain | 22.5N/sq.mm | Requirement |

| Sum of the Tensile Strength | 60.0 N/sq.mm | |

| Glue Shear Strength | ||

| ( Dry State ) | 7500 N/sq.mm | As per ISI |

| Adhesion to plies | 4000 N/sq.mm | As per ISI Req. |

Marine Plywood

Our Marine Plywood is best suited for all kind of Marine applications. Our product is made from tropical hardwood veneers, is preservative-treated under vacuum pressure impregnation with anti-mycological substances to prevent insect infestation and bonded with thermosetting BWP-type exterior-grade resin. We manufacture marine plywood for container flooring that comply with AQS and Lloyd standards.

Applications

Ships, Boats, Crafts, Bridges, Oil High Platforms, Container Floorings and Extreme exterior applications like Floors and Cooling Towers.

Technical Specification

| Name of Test | ISI REQUIRED VALUE |

|---|---|

| Dimension | |

| Length | Max 6mm | Min 0 mm |

| width | Max 3mm | Min 0 mm |

| Thickness | 5% |

| Squireness | 0.20% |

| Straightness | 0.20% |

| Workmanship and Finish | SATISFACTORY |

| PHYSICAL PROPERTIES | |

| Adhesion of Ply | MIN-PASS STD |

| Moisture Content | 5% TO 15% |

| GSS | |

| Dry State | AVG - 1350 N | MIN 1100 N |

| Wet State | AVG - 1000 N | MIN 800 N |

| Z | |

| Parallel to grain | 42.0 N |

| Perpendicular to grain | 25.0 N |

| Sum of Both | 84.5 N |

| STATIC BENDING STRENGTH | |

| MOR | |

| Along the Grain | AVG - 50 N /mm2 | IND - 45 N/mm2 |

| Across the Grain | AVG - 30 N /mm2 | IND - 27 N/mm2 |

| MOE | Along the Grain | AVG - 7500 N /mm2 | IND - 6700 N/mm2 |

| Across the Grain | AVG - 4000 N /mm2 | IND - 3600 N/mm2 |

Flexi

Furniture designing is now an artistic pursuit. Flexi Ply is a boon for designers. Keeping in mind the artisan’s vision of unconventional style, we present the Flexible Virgo ply which can be easily bent into any shape without chipping, cracking, peeling or staining; resulting in a wide range of creations which otherwise would have been impossible. Virgo Flexi Ply is gifted with many specialties. Firstly, no special equipment is required to bend, fabricate or laminate. This makes the work of the carpenter easy as he does not need to gather extra knowledge for using it. Virgo Flexi Ply is available specially in 8×4 ft. size which can be easily bent by hand. A bend radius of as little as 25mm makes this product ideal for tight radius work. Shapes can be formed without intensive effort.

Applications

Furniture and Essential where bowed or curved shapes are required.

Technical Specification

| Thickness | 4mm, 6mm, 8mm |

| Composition | Hot pressed with thermo -setting |

| BWR Grade adhesive | |

| Density | 0.55 gm/cc |

| Bending Radius | |

| 4mm | up to 10 cm radius |

| 6mmm | up to 15 cm radius |

| 8mm | up to 25 cm radius |

| Direction of flexibility | Along the length |

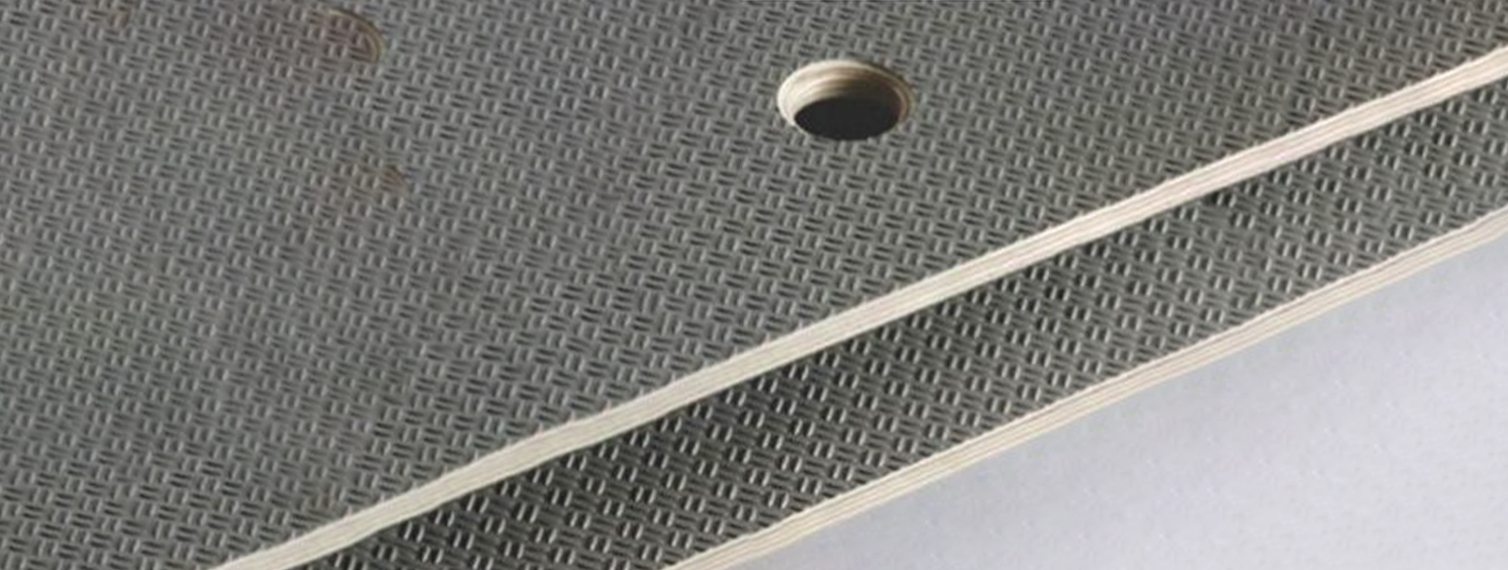

CHEQURERED

Virgo offers a high quality Chequered Plywood and Aluminum Chequered Ply. It is a multi functional product, which can be used in panelling, flooring & decorative purpose etc. Extra impression leads to better ridges and long life holding properties. Its load bearing capacity is also enhanced due to extra compression.

Applications

Cabinets, Almirahs and other furniture, Door Partitions, Shelves and other interior applications; Roofing, Fencing, and other external applications.

Technical Specification

| Name of Test | Required Value/Tolerances | Observed Value |

|---|---|---|

| Length | 2440 (+6mm) | 2440 (+6mm) |

| Width | 1220 (+3mm) | 1220 (+3mm) |

| Thickness | +5% | 12.11, 12.19, 12.30,12.10, 11.95, 12.06, 12.15 (12mm+5%) |

| Squireness | 0.20 | 0.16% |

| Straightness | 0.20 | 0.11% |

| Workmanship and Finish | Satisfactory | Satisfactory |

| Physical Properties Adhesion of Ply |

Min-Pass Std | Excellent |

| Density Test | 0.840gm/cm3 | 0.856gm/cm3 |

| Moisture Content | 5% to 15% | 5% to 15% |

| Tensil Strength Parallel of Grain | 32.50N/SQ.MM | 42.23N/SQ.MM |

| Perpendicular of Grain | 22.50N/SQ.MM | 30.68N/SQ.MM |

| Sum of Both | 60.0N/SQ.MM | 72.91N/SQ.MM |

Catalogues

Plywood has layers of wood pressed together whereas Blockboard has batons of wood

Waterproof plywood uses better quality raw material and can sustain moisture exposure

BIS has mentioned many species of timber in the standard documentation. Any of these are suitable.

Wood is a natural food for termites.

Refers to the separation of layers of plywood